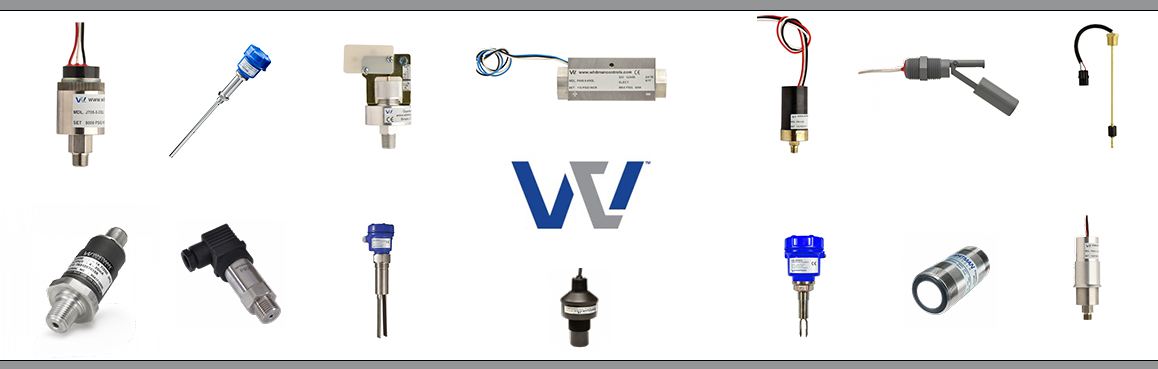

Whitman Controls specializes in the manufacture of miniature pressure, vacuum, temperature, and liquid level switches and sensors.

Whitman is built on our extensive offering of high quality, customized switches and sensors and can build and ship a sensor solution to your exact specifications in two weeks or less, with overnight shipping on in-stock models!

Below, you can find more information on the wide product variety. Reach out to Finn & Conway today for a quote or to get more information.

Whitman controls offers the most diverse selection of pressure switches in the industry. Our diverse line of switches are used across a wide range of applications including blowers, generator sets, off-road vehicles, compressors, wafer ovens, process equipment, flow control devices, pumps, wastewater, heating and cooling systems, and numerous other applications across industries. Our competitive advantage lies in our ability to custom engineer switch and sensor solutions that meet the exact needs of your application and media. Whitman has been working with large OEMs for over 40 years, and our longest running customers are those we have custom designed switch solutions for since our early years.

Pressure Transducers and Industrial Pressure Transmitters provide an advanced alternative for users looking for continuous pressure measurement as opposed to a simple on-off switch. Our full line of pressure transducers provide a wide range of pressure ranges from -14.5 psig to 30,000 psig allowing for a highly diverse operating profile for any end user. Our transducers offer output signals including 0-5V, 0-10V, 1-5V, 0.5-4.5V (ratiometric), 4-20mA and others. Additionally, these can be customized with a diverse selection of fittings and electrical connectors including both integral and external connections.

Whitman Controls offers a diverse range of vacuum switches and transmitters. We pride ourselves with offering the highest quality units in the industry, fully customizable to meet your process control and design requirements. We offer vacuum pressure sensors that are designed to withstand even the harshest weather conditions and to operate reliably in severe vacuum conditions. When the conditions are harsh, Whitman’s vacuum switches thrive! We can build and ship a vacuum switch to your specifications in two weeks or less, or contact our engineering department for a fully customizable solution.

Whitman offers a highly diversified offering of level switched and sensors, ranging from simple single and multi-level liquid level switches to more advanced sensor technologies used in the measurement of liquids and solids across more rugged media applications. These devices come in numerous sizes and materials, with our more advanced vibrating forks and rods providing numerous electrical settings, fittings, and various enclosures for more hazardous environments.

Whitman's full line of level transmitters provide the continuous level and distance measurement up to 50 feet, and for pressure ranges up to 200 meters of water. These devices are ideal for continuous liquid level measurement, or for proximity measurement in process monitoring applications. Numerous options are available for desired output signals, custom lengths, and more rugged environments.

Our more advanced vibrating forks and rods providing numerous electrical settings, fittings, and various enclosures for more hazardous environments. The Series L90 / L91 / L92 Vibrating Fork / Rod Point Level Switches are heavy-duty stainless steel and ideal for measuring the presence of solids and powders across a wide range of media and applications.

The P845 Differential Pressure Switches are rugged and versatile, with excellent by-pass characteristics and the ability to handle a wide variety of media to 6,000 PSIG and set point ranges to 250 PSID. These switches are NEMA 4 rated and can tolerate submersion. They are commonly used across oil and water filter heads to detect when a filter element needs changing. It may be mounted in any orientation and is capable of carrying light to moderate mechanical shock and vibratory loads.

Compound Pressure Vacuum switches allow the end user to control applications where positive and negative pressures exist. Two of our most reliable pressure switches can also be custom designed as compound pressure switches including both the P88 and P100. These units afford the end user a wide range of pressure and vacuum set points, and can be used across numerous media and applications. Much like all our products, these compound switches are field adjustable or factory-set, and come with a vast array of pressure and electrical connections.

Switch Glossary

ACCURACY - The limit of deviation from the set point of a pressure or vacuum switch. It is usually defined in either pounds per square inch, or percentage of full scale.

ACTUATION POINT - See SET POINT. ACTUATION VALUE - The difference between the set point and the reset point.

ADJUSTABLE RANGE - The range within which the switch can be set from the lowest to the highest point, usually expressed in PSI, inches of mercury or PSIA.

BUOYANT FORCE - A body submerged in fluid is pushed or buoyed up by a force equal in magnitude to the weight of the displaced fluid. Buoyancy is dependent on both weight and shape of the float.

CRUSH PRESSURE - The maximum pressure to which the floats may be exposed without deformation. Tanks containing liquids are frequently pressurized. Crush pressure varies with the materials of construction, wall thickness, shape and desired density.

DEADBAND - The difference between the increasing and decreasing readings when the switch is operated between set point and reset point.

DIFFERENTIAL - The mechanical motion lost within the electrical switch element while it reverses itself. This is usually greater in high amperage switches than in low amperage switches.

ELECTRICAL RATINGS - The reed switches are specified as VA (Volt Amps) or Watts. See Table A.

ELECTRICAL SWITCHING ELEMENT - Opens or closes an electrical circuit in response to movement from the pressure or vacuum sensing element. Single pole, double throw (SPDT) snap action switches are standard, may be used as single pole, single throw (SPST). NO/NC circuitry is selectable, but it must be specified at order time.

FLOAT - The liquid level sensor, the portion of the level switch that rises and falls with the changes in the level of a liquid. The float contains the magnet used to operate the reed switch. It is made of various materials and densities to achieve a material compatibility and to be able to float in liquids with various specific gravities.

FORM A SWITCH - A single pole single throw electrical switch - the preferred electrical switch for liquid level devices.

FORM C SWITCH - A single pole double throw electrical switch.

HYSTERESIS - The difference in pressure or vacuum switch response to increasing or decreasing pressure or vacuum.

INTERFACE - The surface between two liquids that have different Specific Gravities, e.g. oil floating on water.

INTERFACED - A float whose buoyancy has been adjusted to float at the interface of the two liquids that have different Specific Gravities.

LIQUID LEVEL SWITCH - An electromechanical device that opens or closes an electrical circuit in response to a change in the level of a liquid.

LIQUID LEVEL SWITCH OPERATION - A float containing a permanent magnet riding on the surface of a liquid. The motion of the float is guided by a stem. The stem contain a reed switch that is actuated by the magnet in the float.

MOISTURE PROTECTION - Our liquid level switches are sealed with potting compound. The only path for liquid to the electrical switch would be through the wires. If the wires are terminated in an appropriate manner (e.g. - NEMA VI connectors), the level switch will meet or exceed NEMA VI.

NEMA VI - A device suitable for submersion.

NORMALLY CLOSED SWITCHING ELEMENT - Current flows through the switch until it is broken by a pressure or vacuum change.

NORMALLY OPEN SWITCHING ELEMENT - No current flows through the switch until contact is made by a pressure or vacuum change.

PRESSURE, ABSOLUTE - A pressure scale based on PSIA "0" or a perfect vacuum.

PRESSURE, AMBIENT - The pressure immediately surrounding a pressure switch. It is usually, but not necessarily, atmospheric gauge pressure.

PRESSURE, ATMOSPHERIC - The pressure caused by the actual weight of the earth's atmosphere. At sea level, atmospheric pressure equals 14.7 psi, 30 inches of mercury, or 408 inches of water, above absolute "0" ("0" PSIA).

PRESSURE, BAROMETRIC - Actual atmospheric pressure in a specified location and altitude. The standard is 29.22 inches of mercury at sea level at 70єF.

PRESSURE, DIFFERENTIAL - The difference between a reference pressure and a variable pressure.

PRESSURE, GAUGE - Uses atmospheric pressure as a zero reference point so there is no compensation for changes in barometric pressure.

PRESSURE, MAXIMUM SYSTEM - System pressure, including surges or spikes.

PRESSURE, PROOF - The maximum pressure which can be applied to a pressure switch without causing irreparable damage. It is usually 150% of the pressure sensing element's rated maximum system pressure.

PRESSURE, SYSTEM - Normal system pressure level not including surges or spikes.

PRESSURE SENSING ELEMENT - The portion of the pressure switch that moves with a change in system fluid pressure. Whitman Controls pressure switches employ capsule, diaphragm, and piston sensing elements.

PRESSURE SWITCH - An instrument that converts a pressure change to an electrical function.

REED SWITCH - A hermetically sealed magnetically operated electrical switch.

REPEATABILITY - The ability of the switch to actuate repeatedly at the desired set point within sensor tolerance.

RESET POINT - After the pressure has reached set point and operated the electrical switch, it must return to the reset point before the electrical switch can return to its original position.

RESET DIFFERENTIAL - The difference between the set point and the reset point. It is caused by the hysteresis of the pressure or vacuum sensing element and the differential of the electrical switch. This is a fixed function of the switch and is not adjustable.

RESPONSE TIME (REACTION TIME) - The amount of time taken between a change in the pressure of the system, and the change in the electrical signal.

SET POINT - The exact point at which the electrical switching element functions. This is generally expressed in PSI, inches of mercury, or PSIA.

SET POINT RANGE - The range within which the switch can be set from the lowest to the highest point, usually expressed in PSI, inches of mercury, or PSIA.

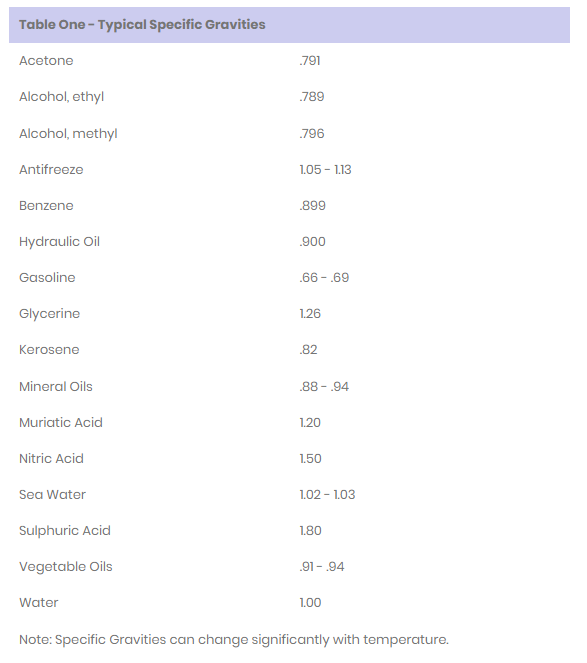

SPECIFIC GRAVITY - The ratio of the mass of the liquid to the mass of an equal volume of water at a standard temperature, typically 60єF. Liquids with a Specific Gravity less than one will float on water. Those with a Specific Gravity greater than one will sink in water.STEM - The portion of a liquid level device about which the float slides. It contains the reed switch, and provides the exit from the tank for the electrical wires. They are made of various materials to achieve material compatibility.

SWITCHING CURRENT, MAXIMUM - The maximum load (amperage) that the electrical switch will carry.

TEMPERATURE, AMBIENT - The temperature immediately surrounding a pressure switch.

TEMPERATURE SHIFT - A change in switch set point due to changes in ambient temperature.

VACUUM - Gauge pressure less than ambient pressure using ambient pressure as a reference.

WORKING PROOF - Maximum pressure which can be applied to a presure switch without causing set point shift.