Your Partners for Level Measurement

Solutions for all types of industries with customed made solutions for even the trickiest of applications.

Customers from all over the world trust in the quality and flexibility of UWT.

Rotonivo® - proven allrounder for point level measurement

The Rotonivo® rotary paddle level switch from UWT operates reliably and maintenance-free and offers a compatible solution for plants for safe level detection in bulk solids. It has all current international approvals for use in gas and dust explosive atmospheres and is one of the first rotary vane detector certified according to SIL 2. Overfill protection and no-load protection are guaranteed for the long term.

The three Rotonivo® rotary paddle level sensor series RN 3000, RN 4000 and RN 6000 cover the complete range of applications, from simple to extreme.

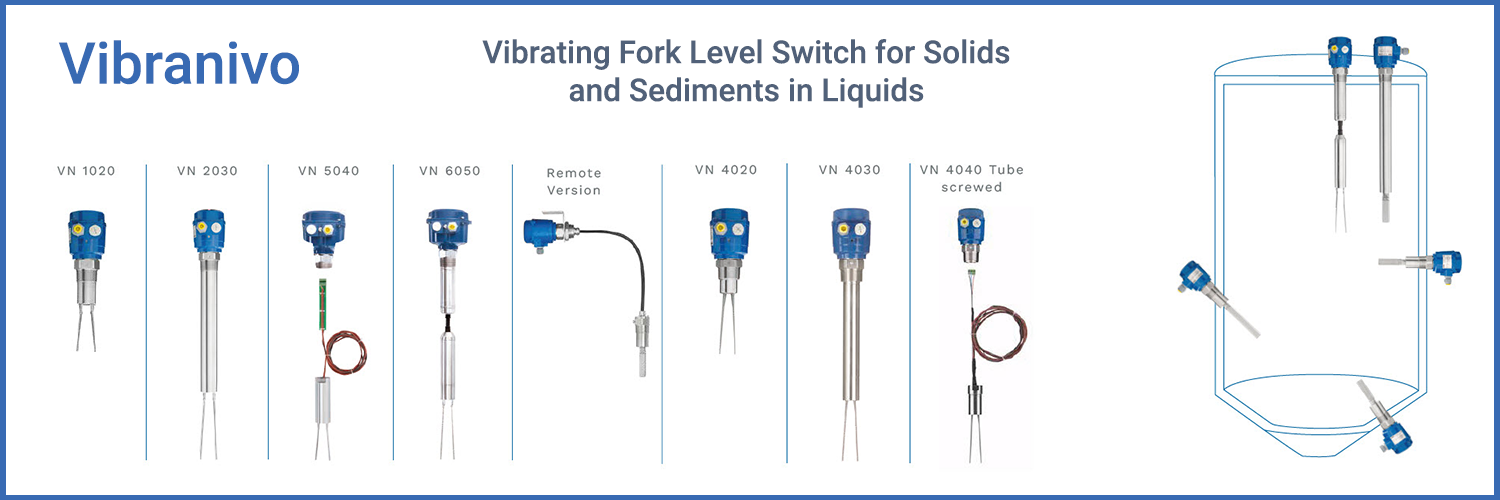

The Vibranivo® - vibrating fork for point level measurement, with its robust stainless steel extension and high sensitivity, is widely used in storage silos and process vessels.

The Vibranivo® vibration level switch is robust, easy to operate and can, via its series range, be precisely configured for each application.

Electronically stimulated piezos cause the fork to vibrate. As soon as the sensor is covered with material, the vibration is dampened and the resulting electrical current change causes the output signal to switch. Once the material level falls below the sensor, it is free to vibrate again and the output signal is reset.

International approvals for use in hazardous locations (gas and dust).

Mononivo® single-rod limit switches for point level measurement are suitable for many applications within the bulk material handling industry as a full, demand or empty detectors for use in storage and process containers.

Electronically stimulated piezos cause the probe to vibrate. As soon as the sensor is covered with material, the vibration is dampened and the resulting electrical current change causes the output signal to switch. The oscillation action of the probe ensures a certain amount of self-cleaning.

The Mononivo® vibration level switch carries international approvals for use within explosive/dusty atmospheres. The robust stainless steel shaft and the device's high sensitivity make it an all-purpose limit switch.

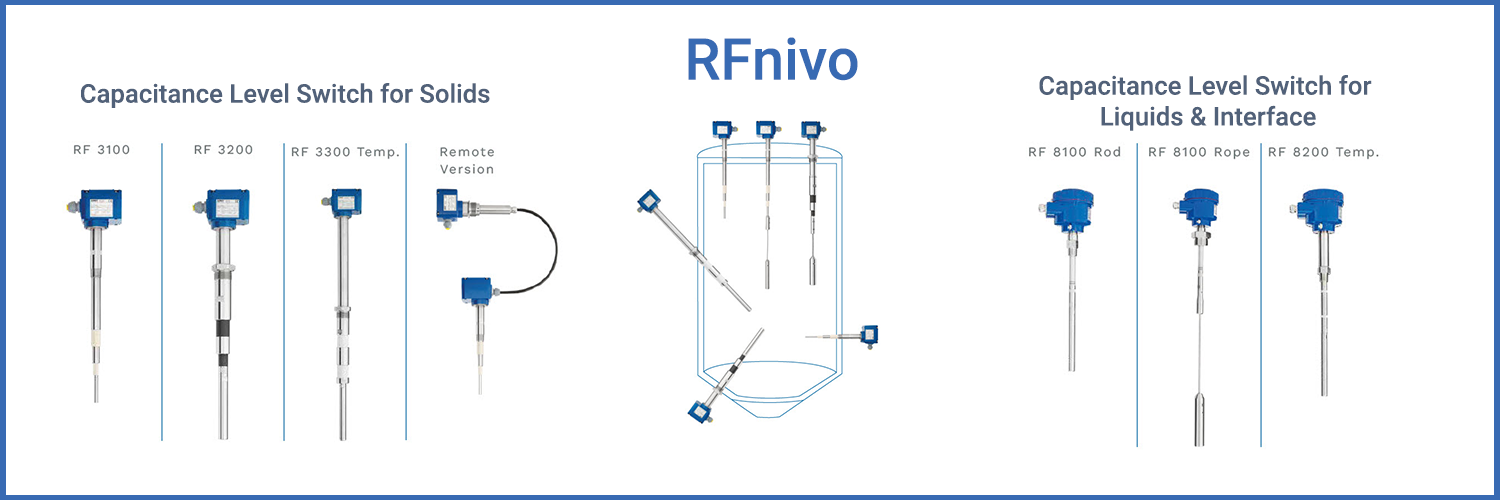

RFnivo® capacitive level switches can be used universally in bulk solids, granulates, powders, pastes as well as liquids and highly viscous oils as full detectors, demand or empty detectors, as level switches as well as overfill protection in silos, tanks, process vessels, hoppers, pipelines and downpipes. In various device versions, they also meet extreme process conditions such as high pressure or extreme temperatures. Their very robust design is also chemically highly resistant to aggressive liquids, slurries or solids.

All instrument types feature Active Shield technology ensures reliable functionality within applications with foam, bridging, material deposits, caking or other types of buildup properties. This additionally increases the functional reliability of the capacitive sensors even when used in viscous, highly viscous media.

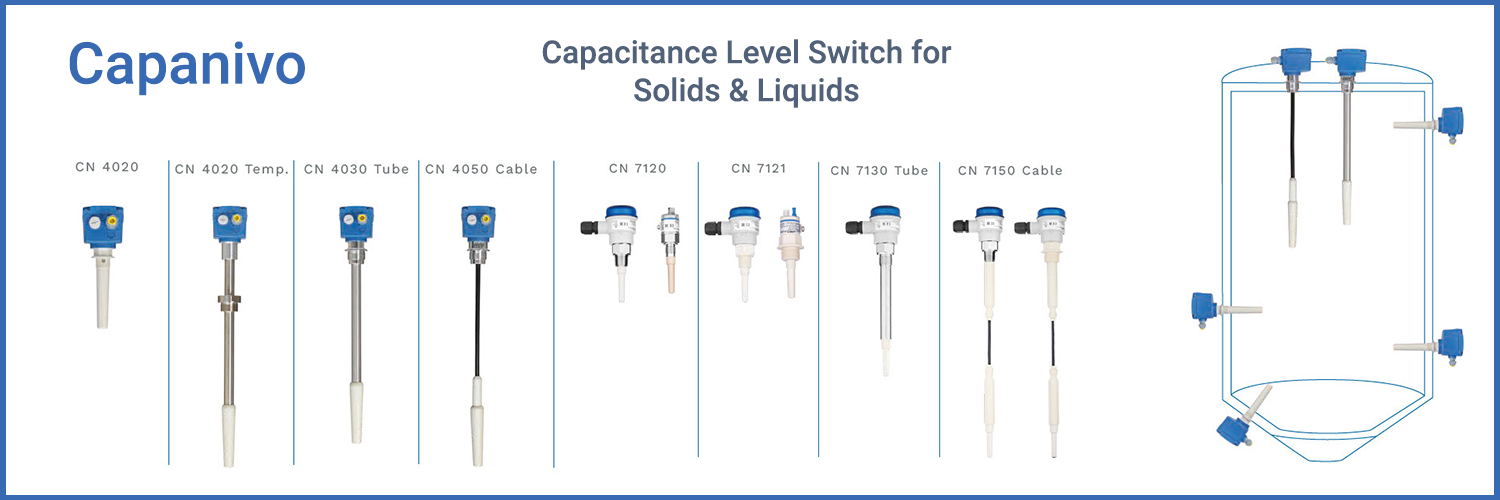

Capanivo® capacitive level switches are universally applicable in bulk solids, granulates, powders, liquids, highly viscous oils, slurries and pastes as full detectors, overfill protection, demand or empty detectors, as level switches or for interface measurement in mixers, silos, tanks, process vessels, hoppers, troughs as well as channels and pipelines. Due to different device versions, installation situations from above, below, the side or with little space requirement can be realized. Further the capacitive sensors of the Capanivo® CN 7000 and CN 8000 series can be used for single media detection (e.g. when foaming) or as sensors for leakage detection.

The robust sensor tip made of fiberglass-reinforced plastic is suitable for use in foodstuffs as well as being resistant to aggressive chemical media. The Capanivo® can be used in storage tanks, silos and process vessels or also in pipes as a level switch, back pressure detector, as dry run protection or as a valve control.

As a capacitively measuring sensor it reacts with a change in capacitance when the sensor tip is touched by a solid, liquid or foaming medium and then switches a signal output (relay or transistor). The versions for solids additionally have active lug compensation due to the built-in Active Shield technology ensures reliable functionality within applications with foam, bridging, material deposits, caking or other types of buildup properties.

In addition to WHG or SIL 2 approval, the various sensors in the Capanivo® series also have international approvals for gas and dust explosion hazardous areas. This makes them the ideal solution for most industries when it comes to level monitoring.

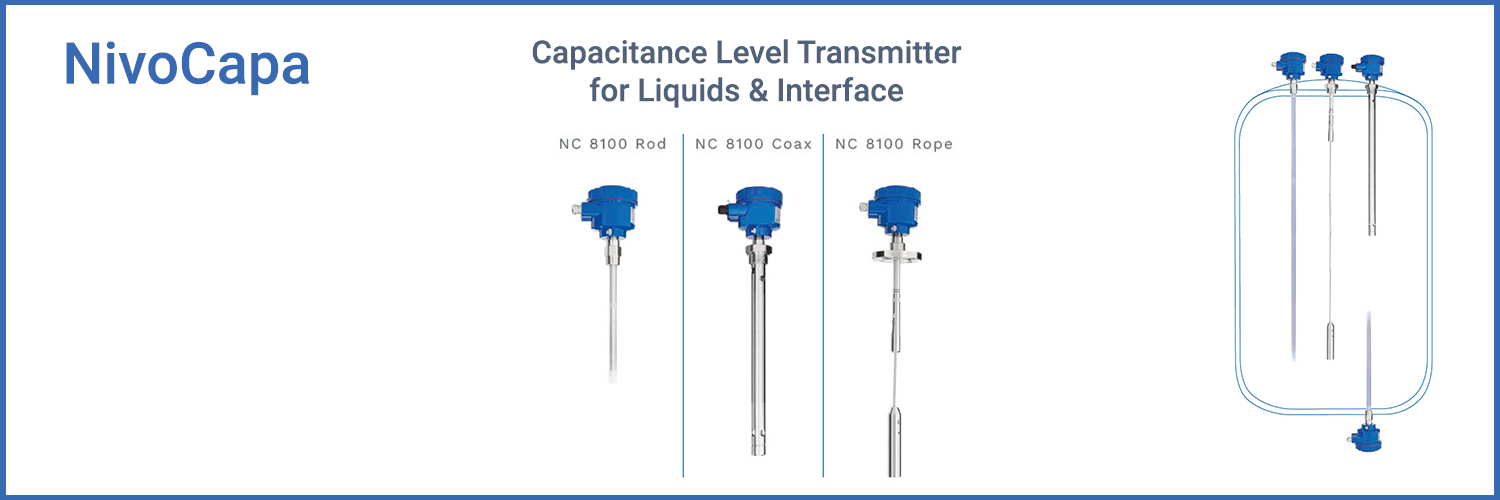

In the field of capacitive level measurement, UWT offers a cost-effective solution with the NivoCapa®.

The extremely reliable and easy-to-use sensor is suitable for level monitoring in a wide range of applications due to the numerous configuration options.

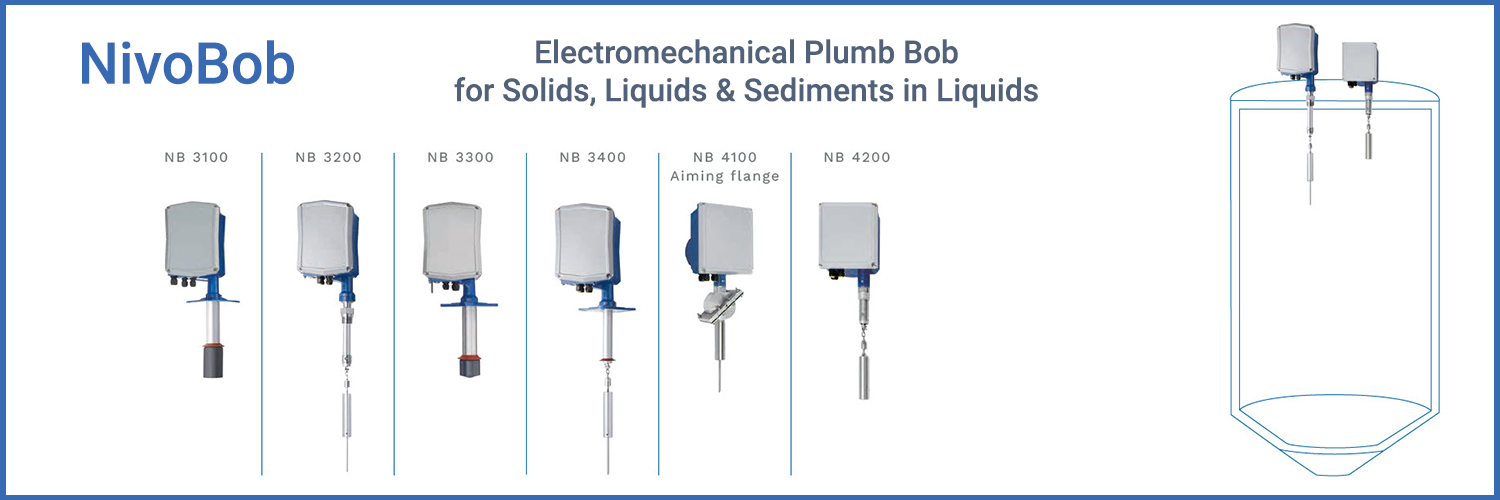

The NivoBob® series of plumb bob sensors from UWT are used for continuous level measurement in storage silos and for interface measurement in various industries. The simple electromechanical measuring method is a classic in level monitoring and suitable for almost all bulk solids, regardless of the DK value (dielectric constant).

UWT offers two different series for this technology area. The products of the 3000 series are suitable for standard applications with increased requirements. With the products of the 4000 series simpler applications can be solved economically.

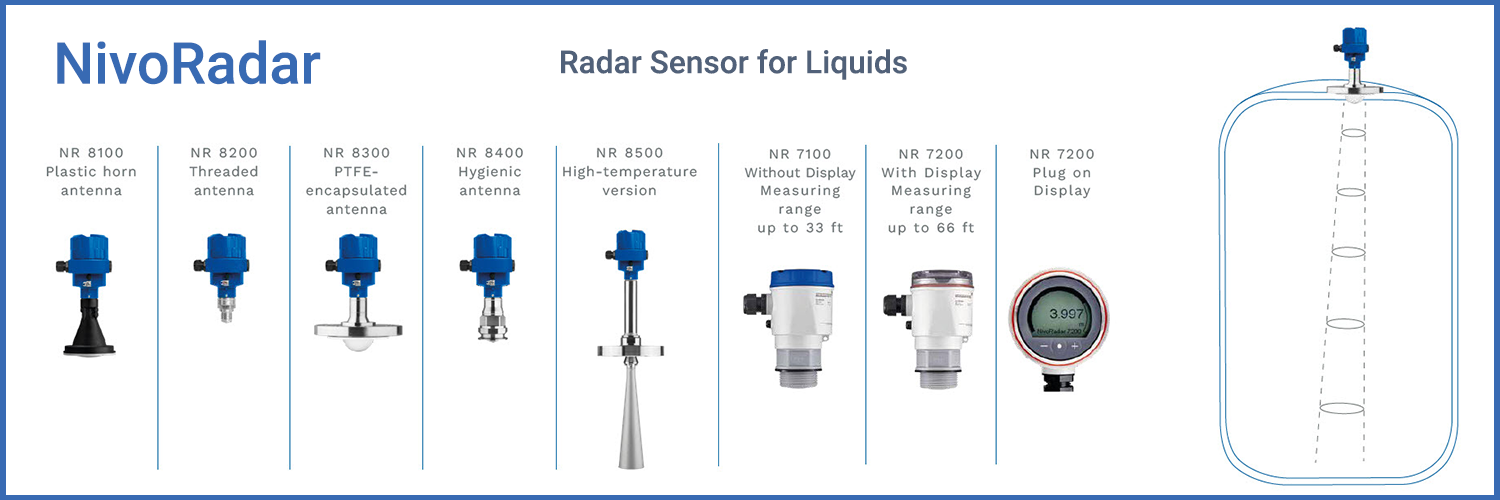

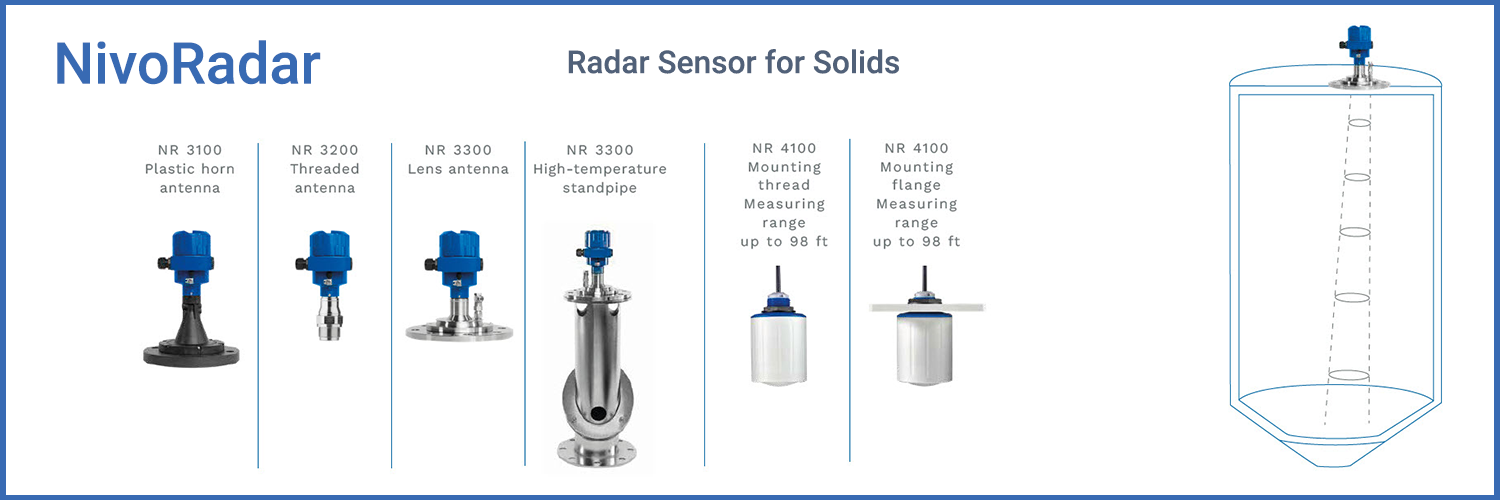

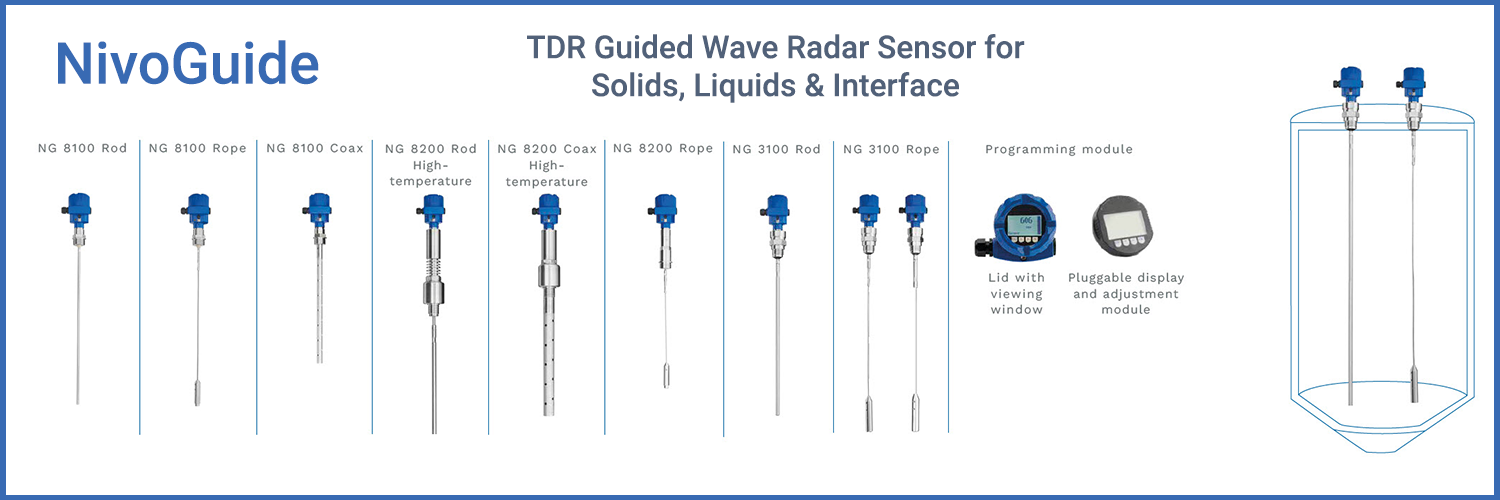

Free-radiating radar sensors can determine the level of a medium without contact. The so-called FMCW radar measurement method (Frequency Modulated Continous Wave) is used for this purpose. The transmitted signal is modulated between two known frequency values (NivoRadar® NivoRadar 76 … 84 GHz) and the difference between the transmitted signal and the echo signal is measured. This difference frequency is directly proportional to the transit time and thus to the distance. The level can then be calculated by adjusting the respective vessel height.

Free-radiating radar sensors are used in both bulk solids and liquid applications.

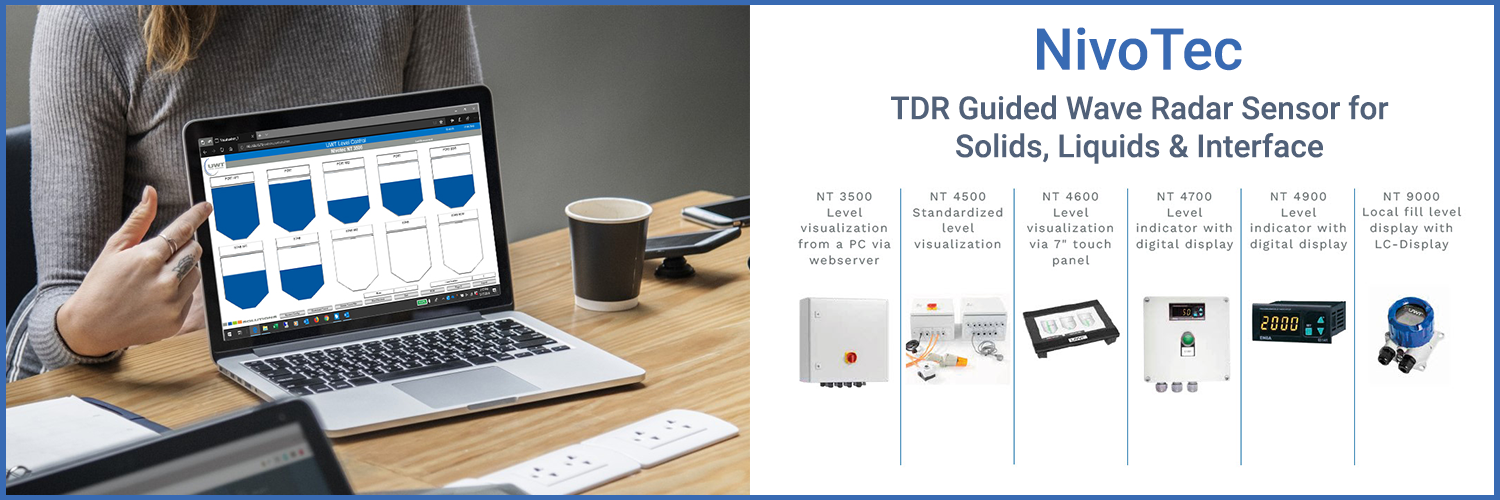

NivoTec®- Inventory Monitoring and Visualization system

Various technologies are available for level indication. Simple LED digital displays for the evaluation of a 4-20 mA signal for installation in control cabinets or up to wall mounted touch panels and web server modules with visualization software. These can then be configured on a project by project basis and adapted to customer requirements.

UWT has standardized product versions of the NivoTec® NT 4000 series, which meet many requirements of a level indicator and monitoring at a cost effective price. The NivoTec® NT 3000 series can be individually adapted to the customer's project. This web server solution meets all requirements of modern silo level monitoring.

Contact Finn & Conway today to learn more

about how UWT can help you LEVEL UP!

csr@finnandconway.com

(708) 599-0103