White Paper

Improve OEE with Faster Weighing Installations, Calibrations and Diagnostics

The Situation

In almost every industry, raw materials and finished product need to be weighed multiple times in the manufacturing process. Weighing vessels and silos is generally accepted as the most accurate and repeatable method to measure their contents, especially for inventory purposes.

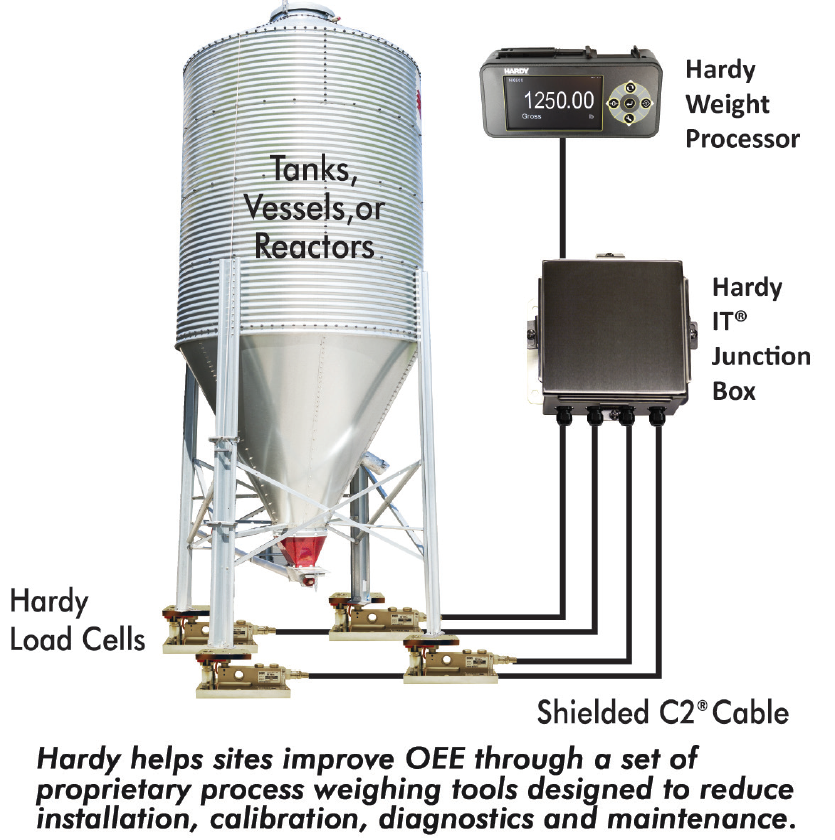

A weighing system can take any of several forms but typically includes one or more load cells that support (or suspend) a weigh vessel or platform, a junction box, and a weight processor or controller. When a load is applied to the weigh vessel or platform, a portion of the load is transmitted to each load cell. Each cell sends an electrical signal proportional to the load it senses via a cable to the junction box. The load cell signals are summed in the junction box and sent via one cable to a weight processor or controller, which converts the summed signal to a weight reading. This weight reading’s accuracy can be affected by the system components’ quality and the system’s installation and operation in your environment.

The Objectives

The objectives are to provide the process with an accurate and stable weight reading, that updates fast enough for the process to be controlled effectively.

Each scale needs to be able to be installed, configured and calibrated quickly and maintained and recalibrated with issues diagnosed easily.

The Challenges

INSTALLATION - There are many factors to consider in vessel weighing such as size, type of vessel, support structure, piping (isolation), vibration (movement), and environment (center of gravity, temp, wind, seismic forces) to name a few. For accurate weighing, the load cells alone must support all the weight to be measured. You can even hang vessels indoors above floor level, saving valuable production space, with the use of load points in tension.

CALIBRATION - The Traditional method used to calibrate and validate industrial scales can be very time consuming, costly, disruptive to production and/or place employees and the manufacturing supply chain at some risk. Usually the higher the capacity of the scale, the greater the impact to production lines. Some companies may be forced or elect to compromise the calibration and complete calibrations with a SPAN load less than the 80% of capacity, thereby deviating from the guidelines laid out for “best weighing practices”. The Traditional process usually takes a long time (hours). The larger the scale the longer it takes (hours and hours). This can drive production (OEE) down and costs up.

VIBRATION - To weigh a vessel as accurately as possible, it must be entirely supported by load cells with associated mounting hardware. If the vessel has an associated mixer or agitator that causes vibration, the weight processor or weight controller must exclude (separate and eliminate) the vibration information from the weight reading.

DIAGNOSTICS – Troubleshooting a weighing system can be time consuming. Often the components are out of reach or installed in enclosures that require specialized tools to open. If the load cells must be indi-vidually unplugged, checked and retested, the integrity of the whole system can be compromised.

The Solution

How HARDY improves OEE with Faster Installations, Calibrations and Diagnostics

Hardy has the expertise and innovative solutions to assist your team in reducing cost and increasing yield, while limiting downtime and achieving improved Overall Equipment Effectiveness (OEE). Hardy products are easy to install, configure, commission, operate and maintain. They are safer and save you time money, raw materials and/or finished product.

INSTALLATIONS - Up to 2X Faster Did you know it doesn’t have to be an adventure to integrate a scale with your PLCs and HMIs. Many systems integra-tors report it can take hours to figure out how to program their PLCs/PACs to talk to a weight processor or weight controller. That’s because they didn’t have the right integration tools.

Our customers use Hardy’s Rockwell Integration Tools on their silo, tank, platform, and bench scales. These best-in-class Add-On-Profiles (AOPs) and Faceplates/AOIs have all been tested, validated, and documented.

Coupled with C2® Calibration and Integrated Technician Diagnostics, installa-tion is up to two times faster, easier and more robust.

CALIBRATIONS - Up to 4X Faster Than

Traditional Methods

Calibrating a load cell or system of load cells, informs the instrument what output to expect at two or more points on the “unique” curve of the load cell or load cell system, so it can accurately interpolate the weight applied across the entire capacity range of the scale. Many plants report that their scales take too long to calibrate and/or repair, holding up production. That’s happening because they don’t know that there’s a better solution.

There are two primary calibration methods. The “Traditional” method that requires calibration weights to be loaded onto the scale in the manufacturing environment every time a calibration is required. Or Hardy’s “C2®” method, which does not require test weights to be loaded for a successful calibration.

Hardy’s C2 “on-site weightless calibration” method approaches the problem by loading each load cell from 0 to 100% with “certified test weights” at their own manufacturing facilities. By doing this step, Hardy captures the characteristics (mV/V/ohm) of each load cell and compensates for its output characteristics. Hardy includes this step, so that every load cell we manufacture is identical (electrically matched). Hardy records and embeds that data in a chip in the load cell for use at our customers manufac-turing facility. The instrument reads this chip and is calibrated to relate a sensor signal to a weight value.

The whole scale can be calibrated and validated with only a small test weight of 5% to 10% loaded for “validation” at your site. This is not a unique technique. This method of pre-calibrating the sensor is also used, for example, in smart pressure sensors.

VIBRATIONS – In most weighing systems, instruments use averaging or filters to reduce the effects of vibration. This can dramatically reduce the update rate, slowing the whole system down. Hardy’s WAVERSAVER® uses a proprietary algorithm that separates and eliminates vibration data from weight data, making the system both faster and more accurate with no decrease in cycle times. Weight readings are both fast and accurate.

DIAGNOSTICS - Up to 5X Faster

Hardy’s Integrated Technician® (IT) helps operators troubleshoot a weighing system and diagnose problems from the front of the instrument or via the PLC, lowering system maintenance costs.

In Hardy Weight Processors or Controllers, IT continuously monitors the weighing system excitation current for shorted or open load sensors, including the cable between the instrument and the junction box, and notifies users of any errors.

Operators can run maintenance tests from the front panel of the instrument through a web browser or from the PLC or DCS. These tests display system weights, voltages, and pass/fail displays to help isolate a problem to the instrument, cabling, or sensors. One scan provides internal references to test the integrity of the instrument, the cable to the junction box, and the junction box itself. This decreases diagnostics and troubleshooting by up to five times over normal methods.

By implementing these simple built-in Hardy process weighing tools, you can increase your Operational Equipment Efficiency (OEE), safety, and reliability today.

Download the White Paper HERE

to Learn More about Hardy Process Solutions